News

Stainless steel pumps in compliance with EC Regulation 1935/2004 for Food & Beverage applications

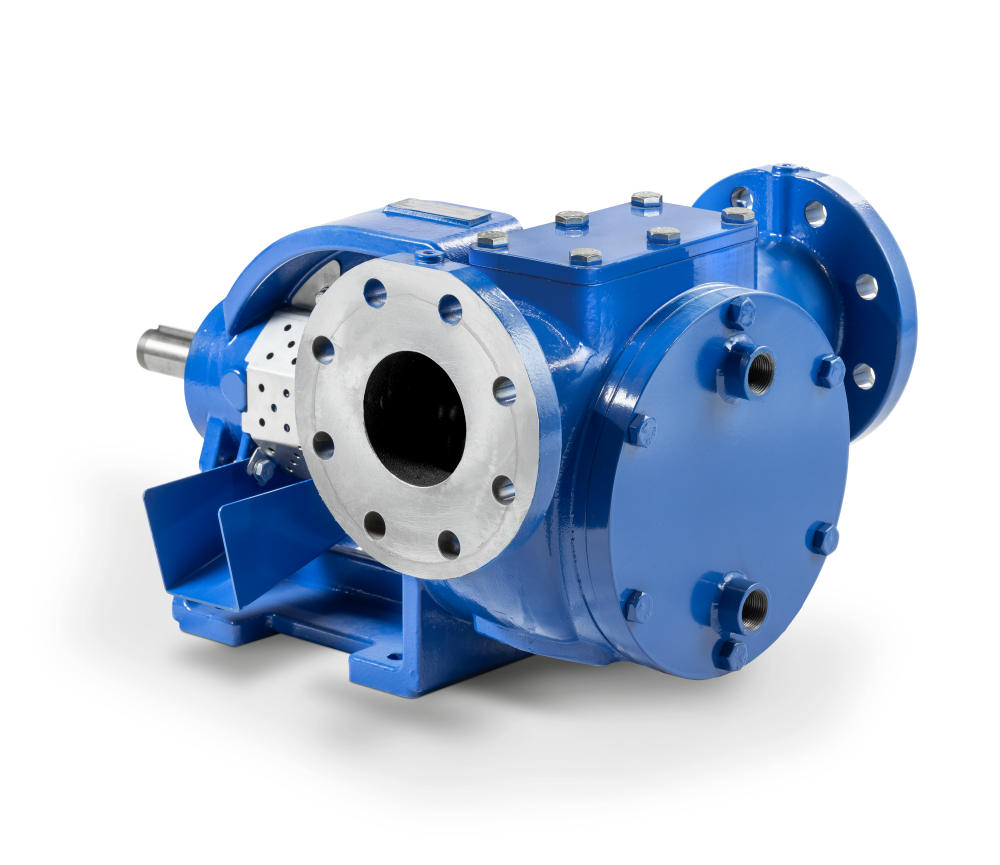

Varisco has expanded its range of positive displacement internal gear pumps conforming to EC Regulation 1935/2004 with a wide selection of additional AISI 316 stainless-steel models.

In the evolving landscape of the F&B (food and beverage) sector, the demand for equipment that is more compliant with unified hygienic rules, valid for all, is changing the construction and storage standards of products and components intended to operate in food processing systems.

For unloading, transferring and dosing operations, conventional cast-iron pumps cannot guarantee that the product will not be contaminated. This is the reason why Varisco has expanded its range of positive displacement internal gear pumps conforming to EC Regulation 1935/2004.

What does the EC 1935/2004 regulation stand for?

EU Regulation 1935/2004 lays down the general principles for the safety of materials and items intended to come into contact with food within the European Union (EU).

This regulation determines the requirements to ensure that materials and items do not transfer harmful substances to food in quantities that could endanger human health, alter the composition of food or deteriorate the organoleptic properties of food.

What are the specific features of internal gear pumps compliant with Regulation EC 1935/2004?

- Kolsterization on rotor, idler gear, cover and shaft. This treatment does NOT alter the stainless effect of the components; Kolsterising is not a surface coating (which could lead to contamination of the product due to the release of particles) but a hardening process achieved by changing the surface atomic structure

- Pin, bushings, and mechanical seals faces made of tungsten carbide with CE 1935/2004 certificate; tungsten carbide is a very hard material, specially used to significantly reduce wear and to prevent any contamination of the pumped product

- Heating chambers on cover and seal holder: in order to check the temperature of the pumped fluid, this series of pumps has heating chambers on the cover and around the axial seal that can be supplied with water, steam or diathermic fluid.